PAGA systems are one of the most important systems on board a FPSO vessel and are utilised to provide key communication and safety instructions.

Due to the harsh weather and often hazardous conditions found on board a FPSO, installing a PAGA systems comes with a set of unique challenges.

Factors to Consider when installing a pAGA system on a fPSO

Understand the Environment

Before diving into the installation process, it is crucial to understand the unique characteristics of a FPSO. Factors such as limited space, harsh environmental conditions, and stringent safety regulations must be considered when designing and installing a PAGA system.

System Design and Planning

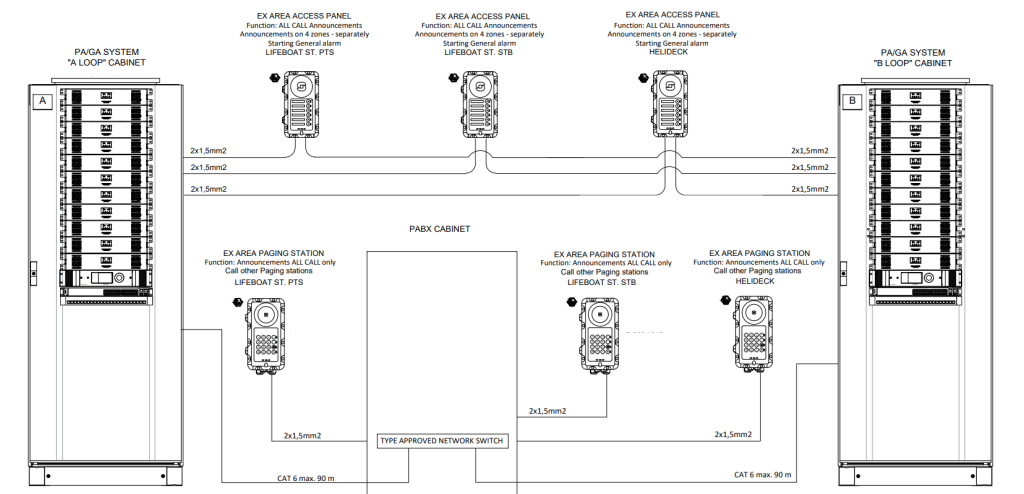

The first step in installing a PAGA system is to develop a comprehensive design and plan, which involves identifying critical areas for audio coverage. For example, living quarters, production areas, helidecks, and emergency evacuation points. Conducting a detailed site survey and collaborating with experienced PAGA system suppliers can help in designing an efficient and effective system.

Equipment Selection

Choosing the right PAGA system equipment is vital to ensure optimal performance and reliability. Factors to consider include speaker types, amplifiers, control panels, power supplies, and emergency backup systems. Selecting equipment that is designed for marine environments and compliant with industry standards is crucial for long-term operation and maintenance.

Integration with Existing Systems

A FPSO already has numerous systems in place, including fire and gas detection, emergency shutdown, and communication systems. Integration of the PAGA system with these existing systems is crucial to enable seamless operation during emergencies. Collaborating with relevant stakeholders and conducting thorough testing and commissioning is essential to ensure proper integration.

Installation Process

Installing a PAGA system requires meticulous planning and execution. Cabling and speaker installation, equipment mounting, control panel placement, and power supply connections are some of the critical tasks involved. Adhering to industry standards and engaging skilled technicians familiar with offshore installations is crucial to ensure a high-quality and reliable installation.

Testing and Commissioning

After installation, comprehensive testing and commissioning must be performed to validate the functionality of the PAGA system. This includes sound level measurements, speaker coverage verification, system alarms, and integration with emergency scenarios. Rigorous testing ensures that the system meets the required performance standards and regulations.

Ongoing Maintenance and Training

Once the PAGA system is successfully installed and commissioned, regular maintenance and training are necessary to keep it in optimal condition. Routine inspections, equipment calibration, software updates, and periodic training sessions for personnel are crucial to ensure the system’s continued effectiveness.

Acoustechno

Sound Solutions

A Vivo Asia website dedicated for all things Sound. Specializing in Acoustic systems, PA systems and intercom systems for harsh and hazardous environments. Learn more

get the best team

The team at Vivo Asia can ensure that all the above factors are covered!

Our experienced engineers can provide accurate system sizing and compliance to applicable standards by ensuring the correct components are selected and the required sound pressure levels are achieved. Vivo Asia uses state of the art simulation software to ensure that direct sound pressure level, signal to noise ration (when noise level study is available) meets the requirements. This ensures that the system is not over sized but appropriately sized to achieve the optimum performance.

Vivo Asia also has partnerships with some of the best brands in the industry for special equipment.