When it comes to electrical safety in hazardous environments whether offshore on an FPSO or in a land-based oil refinery understanding the difference between IEC and NEC standards is essential.

These standards dictate how systems are installed, classified, and maintained to ensure operational safety and compliance.

In this blog, we’ll break down:

- What IEC and NEC stand for

- Key differences between the two

- How each handles hazardous areas (particles, vapors, liquids)

- Examples from real-world projects

What is IEC?

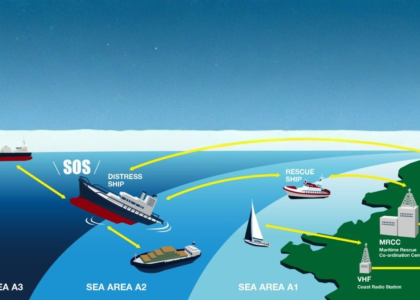

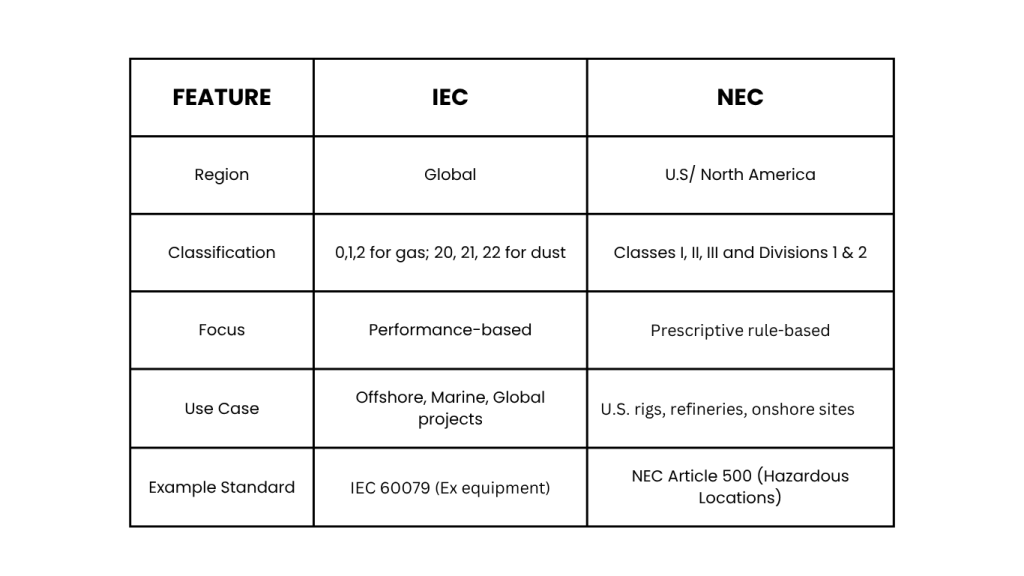

IEC stands for the International Electrotechnical Commission. It’s a global standard-setting body used in Europe, Asia, the Middle East, and widely adopted in the offshore and maritime sectors.

IEC standards like:

- IEC 61892 – Offshore Electrical Installations

- IEC 60079 – Equipment for Explosive Atmospheres

are often used in the design and engineering of platforms, FPSOs, and LNG vessels

What is NEC?

NEC stands for the National Electrical Code, also known as NFPA 70. It’s developed in the U.S. and primarily used in North America and American-operated industrial facilities globally.

NEC applies to:

- Land-based oil refineries

- Petrochemical plants

- U.S.-flagged vessels or platforms

Key Differences Between IEC and NEC

Handling Hazardous Particles and Liquids

One of the most critical roles of both standards is to regulate explosive atmospheres—conditions where gas, vapors, dust, or fibers can ignite.

IEC Example:

A Zone 1 classified area on an FPSO where methane gas may be present during normal operation would require:

- ATEX-certified equipment

- Flameproof enclosures (Ex d) or intrinsic safety (Ex i)

Strict ingress protection (e.g., IP66)

NEC Example:

A Class I, Division 1 area in a refinery handling gasoline would require:

- NEMA-rated enclosures

- Rigid conduit systems with explosion-proof fittings

- Equipment tested per UL standards for hazardous locations

Why It Matters for Your Project

Choosing the wrong standard can lead to:

- Project delays due to non-compliance

- Equipment rework or replacement

- Safety hazards and legal liabilities

If your facility is based in Singapore and serves international oil majors, IEC is likely the expected framework. If you’re engineering for a U.S.-based EPC contractor, expect NEC requirements.

Upgrade & comply with standards

At Vivo Asia, we provide systems that meet international and regional safety standards, from PAGA and telecom to electrical and network solutions for hazardous areas.

Our expert team of engineers ensures that all your emergency communication & sound systems are up to the required standards.

For ore information or requirements reach out to us on contact@vivoasia.com.