Why proper wiring matters

The importance of proper wiring comes down to when a single wiring failure can lead to system downtime, safety incidents, or costly production losses.

Saltwater corrosion, constant vibration, explosive atmospheres, extreme temperatures, and limited access for repairs make offshore wiring far more critical than onshore installations.

In offshore environments, wiring is not just about connecting equipment, it is the backbone of safety, reliability, and uninterrupted operations. On FPSOs, offshore platforms, and vessels, every system depends on correctly designed, installed, and tested wiring to function under harsh and hazardous conditions.

You might wonder what role does it play? well let’s dive in to find out.

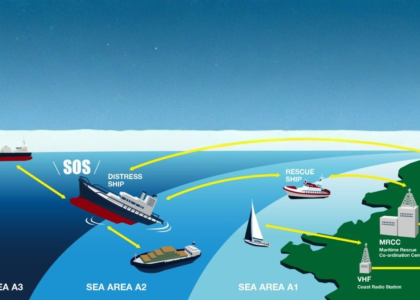

The Role of Wiring in Offshore Systems

Proper wiring directly impacts the performance of key offshore systems, including:

- Telecommunications systems (radio, PAGA, telephony, satellite, and data networks)

- CCTV and security systems

- Fire & gas detection systems

- Navigation and control systems

- Power distribution and emergency systems

In offshore oil and gas facilities, these systems must operate 24/7 without failure. Poor cable selection, incorrect termination, or bad routing can compromise the entire system.

Incidents of faulty wiring

Single faulty wire led cargo ship to crash into Baltimore bridge. A single loose wire on the Dali, a 300-metre (984ft) container ship, was responsible for the deadly collapse of the Francis Scott Key Bridge in Baltimore last year.

Due to problems with the wiring, the Dali experienced two blackouts on March 26, 2024, before losing control of propulsion and steering, leading the container ship to crash into the bridge and kill six highway workers.

Source: Al Jazeera

Wiring in Hazardous Areas

Offshore installations are classified into hazardous zones where explosive gases may be present. Wiring in these areas must comply with strict international standards such as IEC, ATEX, and IECEx.

Key safety considerations include:

- Use of certified flame-retardant and low-smoke cables

- Proper earthing and bonding to prevent static discharge

- Correct gland selection and termination for Ex-rated equipment

- Maintaining segregation between power and signal cables

Reliability in Harsh Offshore Conditions

Offshore wiring must withstand:

- High humidity and salt mist

- Continuous vibration and movement

- Mechanical stress during operations

- Long cable runs with minimal signal loss

Using marine-grade and offshore-certified cables, combined with proper routing, support, and termination, ensures long-term reliability. Well-installed wiring reduces maintenance needs and minimizes unplanned shutdowns.

Upgrade to proper offshore wiring

Offshore wiring is not a task for general installations. It requires experienced engineers and technicians. At Vivo Asia our Expert engineers and technicians are experienced in offshore wiring that reduce rework, delays, and safety risks delivering systems that perform reliably from day one.

Investing in proper offshore wiring is not an option — it is a necessity for protecting people, assets, and production.

For more information reach out to us on contact@vivoasia.com