Why is Factory Acceptance Tests crucial before shipping products for offshore projects?

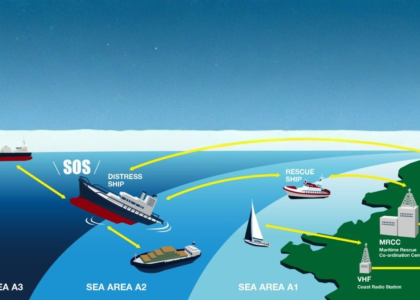

In the offshore oil, gas, and maritime industry, reliability isn’t optional it’s life-saving. Harsh environments, corrosive saltwater, extreme temperatures, and explosive atmospheres demand that telecom and safety equipment perform flawlessly from the first moment. which is why FAT is a critical step in the lifecycle of offshore systems.

Let’s dive into what FAT actually means;

What is Factory Acceptance Testing?

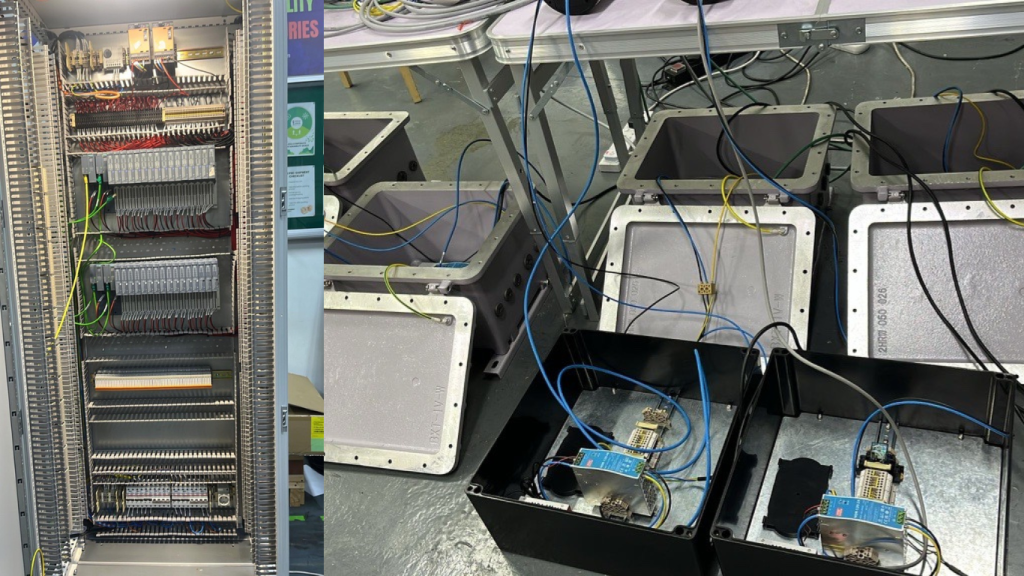

Factory Acceptance Testing is a comprehensive evaluation process conducted before equipment leaves the manufacturer. It ensures that all systems meet technical specifications, regulatory standards, and operational requirements.

FAT is especially vital for offshore telecom and safety equipment, which must function in hazardous conditions without failure. During FAT, engineers perform rigorous tests on:

- Telecommunication systems: Satellite links, VSAT, Starlink, digital radios, and intercoms.

- Safety systems: Explosion-proof CCTV, PAGA systems, fire alarms, and emergency shutdown controls.

- Power and backup systems: UPS, batteries, and redundancy setups for uninterrupted operation.

The testing replicates real-world scenarios, including extreme temperatures, humidity, vibration, and electromagnetic interference, ensuring the equipment can withstand the offshore environment.

Benefits of conducting FAT's

- Minimizes Risk – Identifying defects before deployment reduces the risk of operational failures, downtime, and safety hazards.

- Ensures Compliance – FAT verifies that systems meet international and industry-specific standards such as ATEX, IECEx, and ISO.

- Saves Costs – Detecting issues at the factory stage is far more cost-effective than troubleshooting offshore.

- Boosts Confidence – Operators and stakeholders gain assurance that the equipment will perform reliably under harsh conditions.

Upgrade Your Offshore Systems with Vivo

At Vivo Asia, we specialize in offshore telecom and safety systems for harsh and hazardous environments. Whether you are retrofitting existing installations or deploying new systems, our team ensures all equipment undergoes rigorous FAT procedures. Our expert engineers and technicians are able to customize solutions to your operational needs and budget, helping you upgrade your offshore infrastructure safely and efficiently.

Our services include:

- FAT coordination and supervision

- System commissioning support

- Remote testing and verification

- Equipment upgrades tailored for extreme offshore environments

Vivo Asia ensures that your offshore systems are tested, compliant, and ready for real-world operations.

For more information reach out to us on contact@ivoasia.com