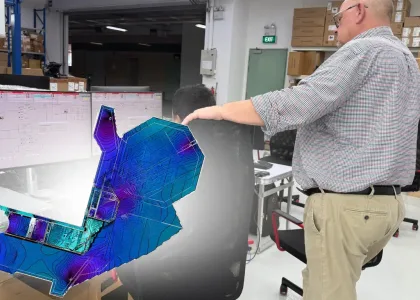

In the rapidly advancing landscape of technology, the role of 3D modeling in system integration cannot be overstated. System integration plays a crucial role in ensuring the seamless collaboration of various components within a complex system. One of the transformative tools that have significantly contributed to the efficiency and accuracy of system integration is 3D modeling.

This blog explores the ways in which 3D modeling facilitates and enhances the process of system integration.

Visualization and Design Clarity

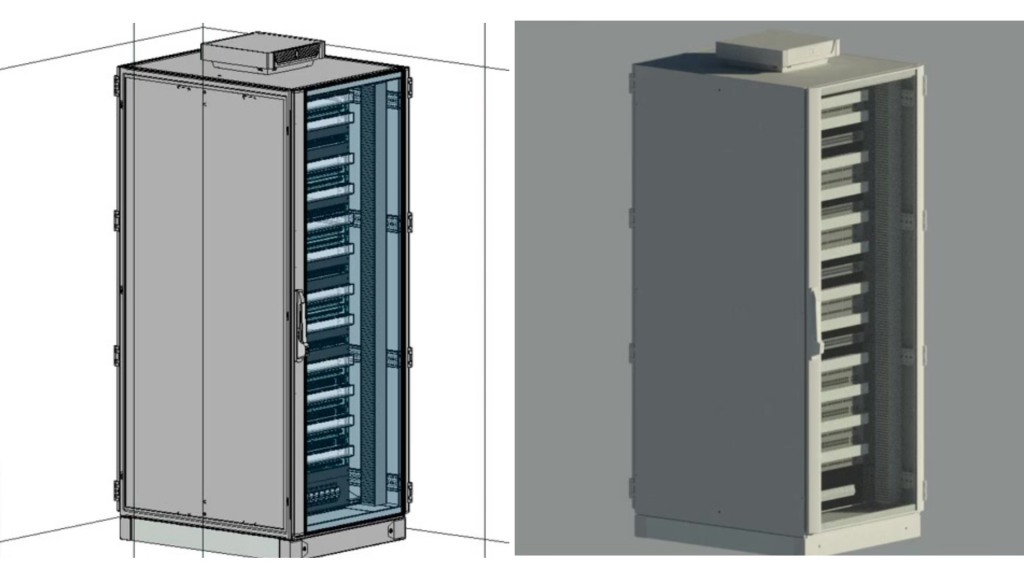

The primary advantage of 3D modeling is providing a visual representation of intricate system components. Engineers and designers can create detailed 3D models that accurately depict the physical and functional aspects of each element within the system. This visual clarity aids in identifying potential conflicts, ensuring that components fit together seamlessly, and minimizing design errors before the physical implementation begins.

Interdisciplinary Collaboration

System integration often involves collaboration among multidisciplinary teams, including electrical engineers, mechanical engineers, software developers, and more. 3D modeling serves as a common ground where professionals from different domains can converge to understand the overall system. With a shared visual representation, communication barriers are reduced, fostering better collaboration and ensuring that each team member understands how their contribution fits into the larger context.

Virtual Prototyping and Testing

Traditionally, system integration relied heavily on physical prototypes, which could be time-consuming and expensive. 3D modeling allows for virtual prototypes that simulate the entire system’s behavior. This virtual environment enables engineers to test different scenarios, identify potential issues, and optimize the system’s performance before any physical components are manufactured. The result is a more streamlined and cost-effective integration process.

Risk Mitigation and Problem Solving

By utilizing 3D models, engineers can foresee and address potential challenges early in the integration process. This proactive approach helps mitigate risks associated with system conflicts, component interference, or performance issues. Identifying and resolving problems in the virtual space reduces the likelihood of costly errors during the physical integration phase.

Documentation and Maintenance

3D models serve as comprehensive documentation of the integrated system. This documentation is invaluable for future maintenance, upgrades, and troubleshooting. With a detailed 3D model, technicians can easily identify and understand the relationships between components, making the maintenance process more efficient and reducing downtime.

Team Vivo is an experienced and expert team of engineers and drafters who use 3D modeling to ensure a seamless system integration process. Offering a new level of accuracy and efficiency, we use 3D modeling for many of the projects we undertake.

Contact us today to discuss your requirements.