Working on FPSO vessels involves unique challenges and risks that demand stringent safety and health measures. In this blog, we will explore the key safety and health measures for working on FPSO vessels, aiming to ensure a secure maritime workplace.

safety and health measures

FPSO vessels play a pivotal role in the offshore oil and gas industry. These massive structures are essential for the extraction, processing, and storage of hydrocarbons at sea.

Rigorous Training and Competency

Before stepping foot on an FPSO vessel, personnel must undergo comprehensive training to equip them with the skills and knowledge needed to perform their tasks safely. This training should encompass familiarization with vessel-specific procedures, emergency response protocols, and an understanding of the vessel’s layout and safety features

Common safety and health certifications include:

- Diving and Offshore Medicine Fitness Certificate – in accordance with UKOOA/ OGUK

- Apply Workplace Safety and Health in Shipyard

- Compressed Air Emergency Breathing System (CA-EBS) Initial Deployment Training (OPITO approved)

Personal Protective Equipment (PPE)

Proper PPE is vital when working on FPSO vessels. This includes helmets, safety glasses, gloves, steel-toed boots, and flame-resistant clothing. PPE should be regularly inspected, maintained, and replaced as necessary to ensure its effectiveness in protecting workers from potential hazards such as fire, chemicals, and falling objects.

Hazardous Materials Management

FPSO vessels often handle hazardous materials like crude oil and natural gas. Safe handling and storage of these substances are paramount. Workers must be trained to recognize potential hazards, use the appropriate protective measures, and handle chemicals in a manner that minimizes the risk of spills or leaks.

Emergency Response Plans

FPSO vessels must have well-defined emergency response plans in place. These plans should include procedures for fire emergencies, chemical spills, medical emergencies, and evacuations. Regular drills and training exercises help ensure that all personnel are familiar with the protocols and can respond effectively in the event of an emergency.

Fall Protection

Working at heights is common on FPSO vessels, and fall hazards are a significant concern. Safety measures such as guardrails, safety nets, and fall arrest systems should be in place to prevent accidents. Additionally, personnel should receive training on how to use fall protection equipment correctly.

Confined Space Entry

Confined spaces on FPSO vessels can present serious dangers due to limited access, poor ventilation, and potential exposure to hazardous gases. Workers must undergo confined space entry training and follow strict entry procedures, including gas testing and continuous monitoring.

Machinery Safety

FPSO vessels are equipped with complex machinery and equipment. Regular maintenance, inspections, and lockout/tagout procedures are essential to prevent accidents related to machinery. Proper training in equipment operation and maintenance is crucial to minimize risks.

Noise and Vibration

Working near heavy machinery and equipment can expose personnel to high noise levels and vibrations, which can lead to hearing loss and other health issues. Adequate noise control measures and the provision of hearing protection should be implemented to protect workers’ health.

Get the Right Team

Ensuring the well-being of personnel not only protects lives but also safeguards the environment and the vessel’s operational integrity.

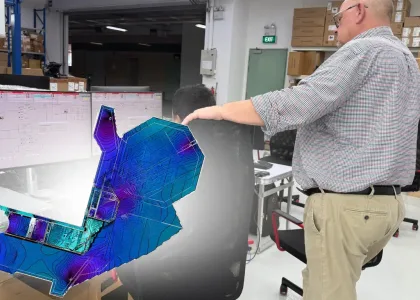

Ensuring the safety and health of workers is a top priority during any project on board a FPSO vessel. Many have strict regulations on how work should be done. Vivo Asia’s team of technicians and engineers are experienced in working on board FPSO vessels and are well-versed in industry regulations and standards.

We provide extensive health and safety training for our employees under the Zero Injuries Framework (ZIF) and have a proven record of risk awareness.