In the vast and intricate landscape of the oil and gas industry, the role of instrumentation engineering services stands as a cornerstone for efficiency, safety, and sustainability. As the demand for energy continues to surge, the need for precise monitoring, control, and automation within oil and gas facilities becomes increasingly paramount. Instrumentation engineering services serve as the backbone of this crucial sector, ensuring seamless operations, regulatory compliance, and risk mitigation.

Precision in Measurement

One of the primary functions of instrumentation engineering services in the oil and gas industry is the precise measurement of various parameters critical to operations. From temperature and pressure to flow rates and composition analysis, accurate measurements are imperative for optimizing production processes and ensuring product quality.

Advanced sensors and measurement devices, meticulously calibrated and integrated by instrumentation engineers, provide real-time data essential for decision-making and process optimization. These measurements enable operators to monitor equipment performance, detect anomalies, and preemptively address potential issues, thereby minimizing downtime and maximizing productivity.

Safety and Environmental Compliance

In an industry as inherently hazardous as oil and gas extraction and processing, safety is non-negotiable. Instrumentation engineering plays a pivotal role in ensuring the safety of personnel, facilities, and the environment.

Automated safety systems, including emergency shutdown systems (ESD) and fire and gas detection systems, rely heavily on instrumentation for accurate detection and rapid response to critical events. Through the seamless integration of sensors, actuators, and control systems, instrumentation engineers create layers of protection that safeguard against operational hazards and mitigate risks.

Optimization and Efficiency

In an industry characterized by its capital-intensive nature and razor-thin margins, operational efficiency is paramount for sustained profitability. Instrumentation engineering services contribute significantly to this objective by optimizing processes, reducing waste, and enhancing resource utilization.

Through the implementation of advanced control algorithms and automation technologies, instrumentation engineers enable tighter control over process variables, thereby minimizing energy consumption, reducing operational costs, and maximizing resource efficiency. From wellhead to refinery, every stage of the oil and gas value chain benefits from the precision and reliability afforded by instrumentation solutions.

Innovation and Adaptability

As the oil and gas industry evolves in response to technological advancements and shifting market dynamics, instrumentation engineering services must continually innovate and adapt to meet emerging challenges and opportunities.

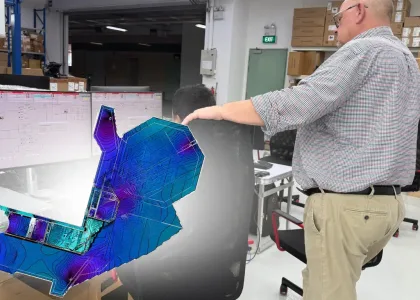

The integration of Internet of Things (IoT) technologies, data analytics, and machine learning algorithms holds the promise of unlocking new insights and efficiencies within oil and gas operations. Instrumentation engineers play a central role in harnessing the power of these technologies, leveraging data-driven insights to optimize processes, predict equipment failures, and drive continuous improvement.

Get the Right Team

Instrumentation engineering services are indispensable to the oil and gas industry, providing the technical expertise, innovation, and precision necessary to ensure safety, optimize operations, and navigate the complex challenges of a rapidly evolving energy landscape.

Team Vivo Asia has over 10 years of experience in drafting and engineering (electrical, instrumentation and telecom) services. We are well-versed in industry regulations and have a streamlined project process. Contact us today!